Vibration Analysis

CCI can be of great assistance in identifying the sources of noise-inducing vibration in both new and existing facilties. CCI can also include sound and vibration measurement into our commissioning scope, and assist the owner or design team with writing proper testing specifications.

CCI has numerous vibration certified technicians and professionals on staff. Call today to see what vibration anaysis by CCI can do for you!

What is Vibration Analysis?

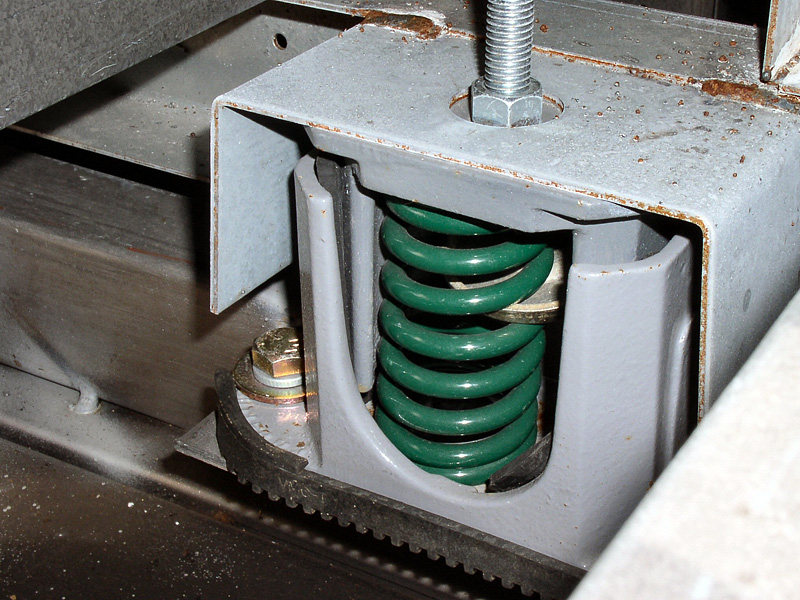

Vibration Analysis starts with a site inspection to verify that systems are properly installed with the necessary means of isolation, and that those isolation systems are properly adjusted. Too often, isolation systems are found that have never been properly adjusted, or in other cases there are other building systems that have been installed in a fashion that defeats the isolation system. Any of these issues must be discovered and corrected prior to vibration testing and analysis of the system. It can also be used to pinpoint the source of troublesome vibration in buildings and other structures and recommend remedial action.

Vibration Analysis starts with a site inspection to verify that systems are properly installed with the necessary means of isolation, and that those isolation systems are properly adjusted. Too often, isolation systems are found that have never been properly adjusted, or in other cases there are other building systems that have been installed in a fashion that defeats the isolation system. Any of these issues must be discovered and corrected prior to vibration testing and analysis of the system. It can also be used to pinpoint the source of troublesome vibration in buildings and other structures and recommend remedial action.

Why Perform Vibration Analysis:

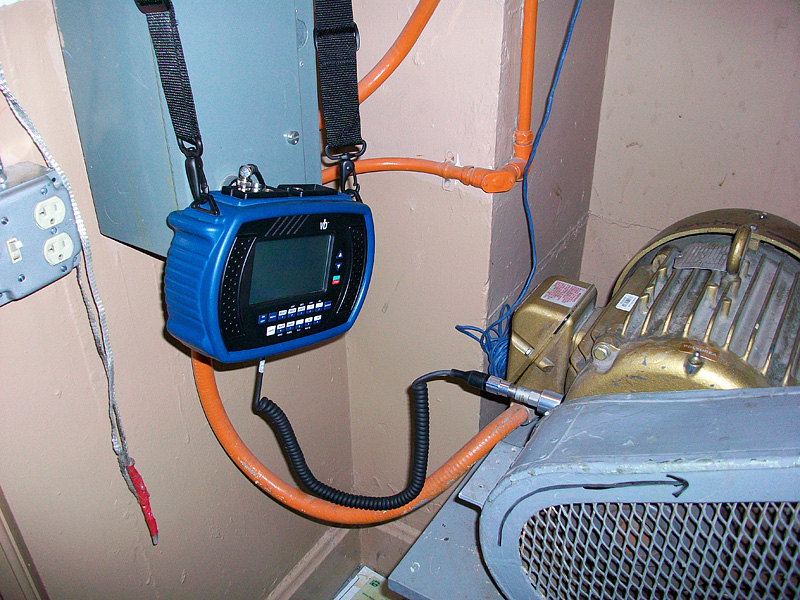

Performing vibration analysis at equipment start-up is done to establish an operating baseline. Trending this data over a consistent period of time (usually bi-annually) is a powerful tool, allowing early detection of bearing or gear faults, belt or sheave faults, and equipment imbalance or misalignment. This allows the owner’s operating staff to schedule equipment downtime for repairs, overhauls, or replacement instead of performing costly emergency repairs. Vibration analysis is typically used on all forms of rotating machinery, including motors, fans, blowers, belts and chain drives, gearboxes, couplings, centrifugal pumps, piston pumps, sliding vane pumps, propeller pumps, screw pumps, piston compressors, centrifugal compressors, and screw compressors.

Vibration analysis is also used to evaluate the performance of vibration isolation systems. This is critical in ensuring that vibration is not being transmitted to the building structure at start-up or over time, as equipment or machinery begins to age and wear. It is not unusual to discover that new isolation systems are not performing properly, but because the equipment is new, no vibration is noticed in the structure until the equipment has been in service for some time (and usually long enough to be out of warranty).

Acceptance Testing by Vibration Analysis:

Vibration analysis is frequently specified to be performed on new installations, but is rarely done because most people have little understanding for what it is, and what constitutes acceptable levels of vibration. CCI recommends that vibration analysis be included as a component of acceptance testing for all new equipment installations over 3 horsepower. CCI not only has the expertise to perform the required expertise and analysis, but also the expertise to evaluate the work performed by others.